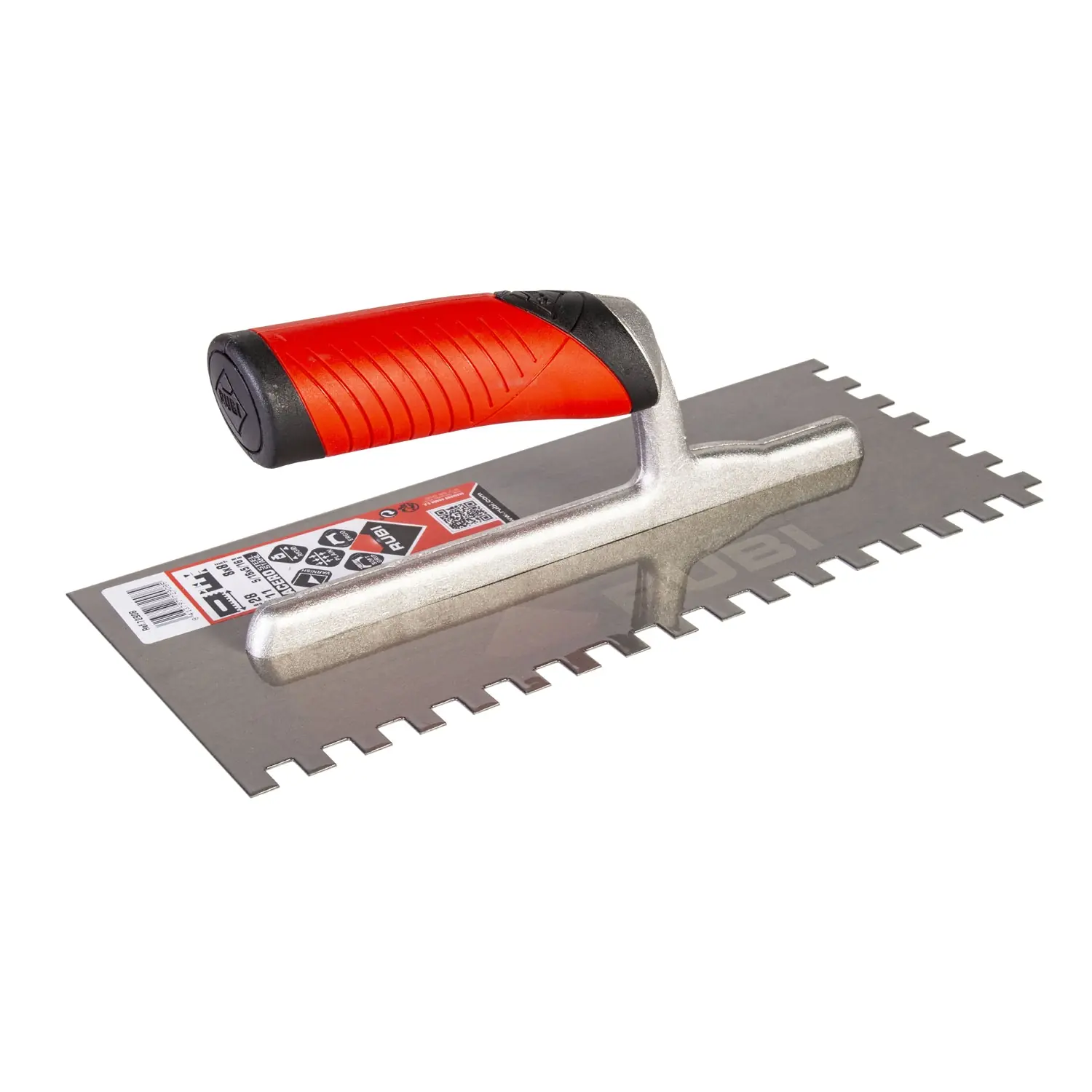

RUBI SILVER wheels are made of sintered tungsten carbide. Each wheel is rectified in a unit manner so that each diameter has an incision angle according to its function and use. Each diameter of wheel offers different results and yields, depending on the type of ceramic material.

The high wear resistance offered by the RUBI carbide wheels guarantees the professional a life and quality of finishing at the height of the expectations. For the correct operation of SILVER wheels and wheels, the scoring must always be continuous and homogeneous, without excessive pressures or unnecessary passes.

Adapting the diameter of wheel and the way of scoring with each type of material will always guarantee the best results.

SILVER RUBI scoring wheels are suitable for scoring, and subsequent separation of ceramic tiles of any type: tile (BIII), glazed stoneware (BIb – BIIa), rustic or extruded stoneware (AIb – AII) and of course porcelain stoneware (BIa), with difficulties of cuts between low and medium.

SILVER scoring wheels have been designed, mainly to work with ceramic materials that have glazed or natural surfaces with smooth and / or slightly rough finishes.

The shafts of SILVER wheels have a triple fluted geometry (design and RUBI patent), to ensure a correct assembly on the manual cutter, as well as a firm fixation and firm and vibration-free scratching. Forming the best combination to always obtain the best results.