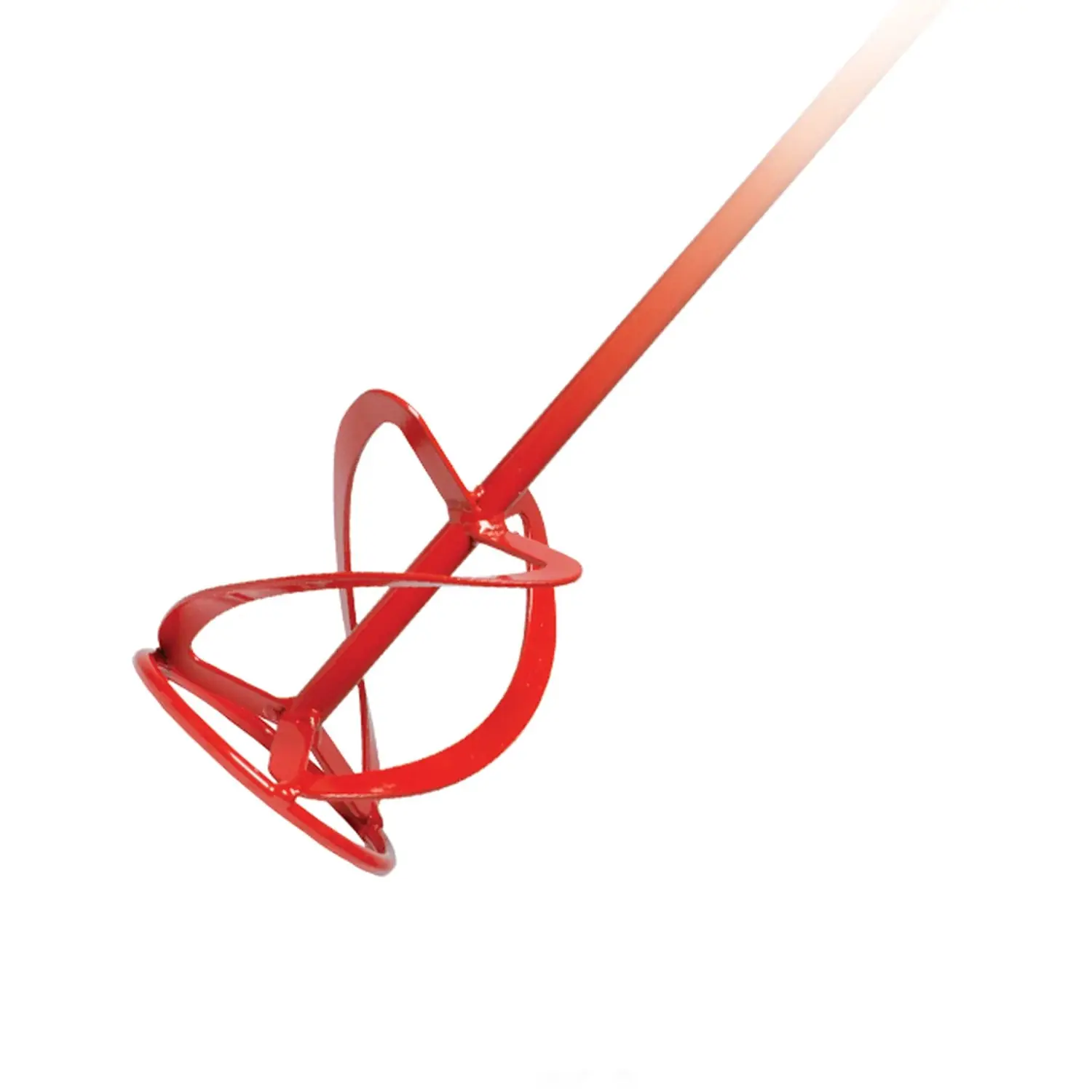

RUBI has a wide range of paddles for mixing cementitious mortars and other high density or low fluidity materials.

This range of mortar mixer paddles has a M14 x 2 thread connection which is directly adaptable to all RUBIMIX electric mixers and to most other brands.

The mixer paddles for cementitious mortars have a head designed to perform a movement from the bottom up. With mortar mixer paddles, the material rises, at a low speed, up the inside of the paddle head and then come back down the outside.

This action produces highly viscous homogeneous mixing of materials such as mortars, cements and especially improved cementitious adhesives (type C2) for ceramic tiles. This head design allows the user to work with less effort and a greater mobility.

The 3H rods have a 3-blade propeller head for a greater mixing efficiency.

This design increases the performance by 15% with respect to the 2-blade propeller head.

In addition, during mixing, the power for the electric mixer is reduced, achieving a greater durability of the electric tool.

The 3-blade head generates fewer vibrations; therefore, the user is able to work in greater comfort.

At RUBI we know how people work in every country in the world, we know the demands of ceramic tilers and we have knowledge of all materials used for installations and repairs. For these reasons RUBI is a recognized brand and clearly focused on a professional and demanding industry. That’s why RUBI offers you all the knowledge and experience to manufacture high precision tools. The high demands of our customers and the market has led us to put our expertise into designing tools and products for cutting and fixing ceramic tiles as accurately as possible.